Using the latest concrete polishing equipment and concrete polishing techniques, it is possible to grind old or new floors to a smooth, glossy finish.

CONCRETE POLISHING

The complex system involves, intially grinding the floor to acheive the level of aggregate exspoure that we are after, grouting all the defects, minor hair line cracks and small pine holes. After which we apply denisfiers to harden the floor in preparation for polishing. Once the floor is ready to polish it can be a 7-8 step process to acheive a mirror sheen over the floor, with a final seal and buff to product the surface and bring the colour out the floor.

EPOXY COATINGS

Whether its a garage, workshop floor or shop front, Epoxy floor coatings can be a good way of bringing a dual floor back to life. Not only the look of a nice clean, smooth, shinny floor, but also the protection against contaminants that seep into the concrete surface making the job of getting a clean, near impossible.

BENEFITS OF POLISHED CONCRETE

Reduce Dust

Over time the concrete floor surface can wear and break down and produce concrete dust, but the full grinding and polishing process will prevent the top surface from ever breaking down into a power or dust.

Increased Density

The polishing process actually increases the hardness of the concrete, which means that the density and overall compression strength will be improved, making the floor more resistant to dirt, grease, oil, tire marks, abrasions, or impacts.

Appearance

Polishing Concrete floors produces a near perfect reflection, which will significantly improve the brightness of the area and can increase lighting ambiance by up to 30%. The final finish is an attractive and fresh look that will enhance any space.

Low Maintenance

Unlike tiles, timber or painted surfaces, polished concrete does not need heavy cleaning, waxing, repainting or treatment. With less grain in the surface, less dust and dirt is trapped and therefore minimises cleaning. The high gloss finish minimises any moisture seeping into the concrete avoiding discolouring and damage to the concrete.

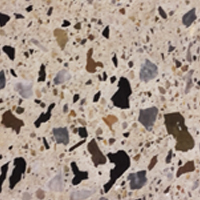

FULL CUT

PARTIAL CUT

SALT & PEPPER

DISCLAIMER - CLICK FOR INFO

It is a common issue surrounding the Polished Concrete Flooring industry of the perceptions of some levels of exposure of aggregate and also the importance of even, well placed concrete. It is important thus, both the client and floor preparation contractor be clear on what is being delivered. As shown on our website, we have provided three (3) samples of the different levels of exposure during the grinding process,

‘Salt & Pepper’, being the fine stone in the sand.

‘Partial Cut’, exposing nil to medium aggregate.

‘Full Cut’, exposing full aggregate in the floor.

With all best efforts and intentions, it is highly unlikely to get an even spread of exposure across a floor area, mainly in regards to ‘Salt & Pepper’ finish. Because of the minimal amount being ground off the slab it can lead to exposing marks that may appear in the concrete. For example, trowelling machine marks, boot marks, knee boards, screed lines etc. As more is cut of the floor, there is less chance of these marks showing up in the final product. It is important to note that this is not a regularly occurrence, however it does happen enough to warrant making mention of this. As Floor Finishers some of these issues are totally out of our control. It is also important to note that concrete is a natural product, it can move over time producing small hairline cracks as well as inconsistencies within itself. Therefore if given a small sample of a floor in a photo etc, it may seem different when given the total area size.

DELLATORRE CONSTRUCTION

E: todd@dellatorreconstruction.com.au

PO BOX 222, STRATHALBYN SA 5255

SA BUILDERS LICENSE No. BLD 272749